Regular racking inspections are key to avoiding unexpected accidents – and discharging your legal duties. HSE and SEMA guidelines both mandate an annual review of all racking and storage equipment, carried out by a “technically competent” inspector who’s equipped to assess the condition of your racking system(s)

Failure to abide by these guidelines and regulations could invalidate your insurance policies, and expose your business to legal jeopardy in the event of a workplace accident. It is also worth noting that the average fine for non-compliance with health and safety regulations is substantial.

With over 45 years of hands-on experience, we’re ideally placed to carry out your annual racking inspections – and ensure that you’re fully compliant with all relevant regulations. We offer in-depth racking inspections by racking inspectors who are either SEMA-approved Racking Inspectors (SARI) or recognised by HSE as technically competent.

Like most qualified racking inspectors, we use a rigorous inspection process designed to flag any issues with your racking system. We can schedule an inspector to visit your premises yearly, inspect your racking and compile a detailed report that provides a prioritised list of issues and the actions required to bring your racking up to spec.

We understand that you’re under pressure to deliver efficiencies. While we always put safety first, we work hard to ensure that the solutions we recommend are practical and proportionate.

A Detailed And Thorough Racking Inspection Service

Most warehouse racking is designed to withstand minor knocks, scrapes, and bumps. Manufacturers understand that warehouses are busy places, and most systems are built using beams, uprights, braces, floor fixings and locking clips capable of withstanding daily wear and tear.

Unfortunately, racking is still susceptible to damage from machinery like forklift trucks or robotic pickers. Everyday wear and tear will also take a toll on nuts, bolts, clips, pins, support braces and other components that are integral to the stability of your storage system(s).

Warehouse Racking Damage

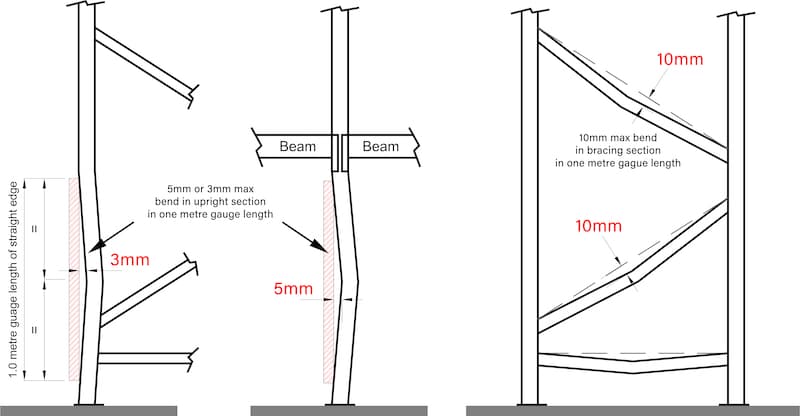

When one of our racking inspectors attends your facility, they will thoroughly examine all racking and storage equipment, keeping SEMA recommendations about tolerances and acceptable limits in mind. They will examine your inventory for any sign of damage, twisting, missing items, or overloading, working through a thorough checklist that covers your racking:

- Upright posts

- Base Plates

- Frame Bracing

- Beams

- Beam Safety Locks

- Fixings

- Safety Equipment

They will then compile a written report that contains a complete summary of their findings – and a full list of actions required to maintain the safety of your warehouse racking.

Our inspectors are experienced and helpful. They also use a simple ‘traffic light’ system to record the levels of risk present during our inspection – providing you with clear information about the condition of your racking and allowing you to prioritise any remedial work.

The inspections we offer currently include:

Pallet Racking Inspections

Because pallet racking is designed for larger, bulkier items, it is loaded and unloaded with forklift trucks, a regular operational activity that inevitably results in occasional collisions. These collisions can damage your racking systems, causing anything from severe bends in the metal frames to bangs, dents and chipped paint.

Whatever the damage, these collisions can also reduce the strength of the racking system, so regular checks are essential to ensure continued safety. When we inspect a pallet racking system, we pay particular attention to the integrity and load-bearing capabilities of the system, noting any damage to structural supports and ensuring that you’re aware of all possible risks.

Longspan Racking Inspections

Longspan racking is strong and is not loaded by forklift trucks; for this reason, it's less frequently damaged than other types of racking systems and is easier to repair. However, you can use Longspan to store heavy and bulky goods, so inspecting it regularly to check for any issues is vital.

When we inspect longspan racking, we look for the telltale signs of structural damage and note down any marks indicative of sustained wear and tear. You'll get an itemised list of possible problems and actionable advice on preventing further damage.

Inspections For Other Types Of Racking

Where required, we can also undertake inspections of less common storage systems, like coil, tyre or cantilever racking.

Are Racking Inspections A Legal Requirement?

All racking and storage equipment is classed as work equipment under the Provision and Use of Work Equipment Regulations 1998 (PUWER). PUWER mandates that all work equipment is safe for use, maintained in a safe condition and inspected to ensure it is correctly installed and does not subsequently deteriorate.

In addition to these general guidelines, the Health and Safety Executive's HS76 sets out more specific rules for the regular inspection of racking systems: demanding that regular, in-house inspections are accompanied by a more thorough inspection by a "technically competent person", arranged at 12-month intervals and accompanied by a detailed written report.

Then, there are SEMA's own guidelines on the subject. SEMA advocates for "a rigorous approach to rack inspection, maintenance and repair through a regime of (typically) daily, weekly and annual (expert) inspections." which aligns with the HSE's regulations.

SEMA is not a government body or third-party regulator, but they are widely respected as the foremost trade body in our industry. They are generally considered to set the standard, so it's always worth listening to what they have to say.

There's a more general health and safety consideration at play here, too: Beyond the legal requirements, it's worth noting that racking systems can and do become damaged, twisted, or overloaded over time.

Failure to conduct regular inspections significantly increases the risk of an adverse event. While trying to duck the expense of an annual inspection regime can be tempting, it's generally much more cost-effective to catch potential problems in their infancy.

Do I Need To Employ SEMA-Approved Racking Inspectors?

HS67 demands that a technically competent person carry out annual racking inspections but does not mandate the use of a SEMA-approved racking inspector (or SARI). The actual definition of a technically competent person given in HS67 is:

“a trained specialist within an organisation, a specialist from the rack supplier, or an independent qualified rack inspector.”

Of course, it's worth noting that a SEMA-approved racking inspector will automatically qualify as a technically competent person – removing any uncertainty about your adherence to the relevant regulations.

However, there are other ways of demonstrating technical competence. Some of our racking inspectors have decades of hands-on experience, a sound working knowledge of the ratings and specifications of all commonly found racking systems, and a proven track record providing racking inspections for household names.

Sourcing Repairs And Replacements

If your racking shows signs of significant structural damage, we can help you repair or replace damaged parts. A warehouse racking specialist with over 45 years of experience, we're here to help you source new beams, uprights, braces, floor fixings, nuts, bolts or locking pins.

We can also help you design and install accessories to mitigate further damage, including barriers, corner guards, load signage, and anti-collapse mesh.

Discuss Your Requirements Or Find Out More

To discuss your requirements or find out more about our racking inspection process, get in touch using the contact form below. A member of our racking inspection team will get back to you as soon as possible.