- Mezzanine Floors

- Solutions

- Multi-Tier Mezzanines

- Mezzanine Pallet Safety Gates

- Mezzanine Staircases

- Mezzanine Handrails and Balustrades

- Mezzanine Decking

- Fire Protection for Mezzanine Floors

- Mezzanine Lift Shaft Design and Installation

- Resources

- Mezzanine Floor Calculator

- Mezzanine Floor Regulations and Building Control

- Self-Storage Mezzanine Floors

- Self-Storage Units

- Resources

- Self-Storage Site Selection Information

- Calculating The ROI of Self-Storage Conversions

- Planning for Automation in Self Storage

- Racking & Shelving

- Services

- Racking Design

- Racking Manufacture

- Racking Installation

- Racking Inspections

- Retail Racking And Shelving Systems

- Solutions

- Cantilever Racking

- Pallet Racking

- Coil Racking

- Longspan Shelving

- Tyre Racking

- Kimer Racking

- Live Storage Racking

- Drive In & Drive Through Racking

- Clip Shelving

- Mobile Shelving

- Custom Fabrications

- About Us

- USS Case Studies

- Self-Storage Fit-out For Raked Ceiling Building

- Mezzanine And Staircases For Entertainment Venue

- New Mezzanine And Staircases For Major Retailer

- Mezzanine Pallet Safety Gate

- Self-Storage Fit-Out Project For Brand New Facility

- Warehouse Racking, Wire Mesh & Shelving for New Warehouse

- Self-Storage Partition System & Components Installation

- Self-Storage Store Mezzanine And Staircases

- Multi-Tier Mezzanine For Logistics & Distribution Facility

- Warehouse Plant Platform

- Self-Storage Facility Space Expansion

- Mezzanine Floor For Distribution Warehouse

- Bespoke Feature Staircase & Mezzanine

- Single Level, Multi-Use Mezzanine

- Mezzanine For A New Building

- Mezzanine Floor For Plumbing Supplies Warehouse

- New Racking System and Mezzanine Floor

- Car Park Conversion To Self Storage Facility

- Pallet Racking and Cantilever Racking For Warehouse

- Two Mezzanine Floors For Self-Storage Facility In Birmingham

- Our Accreditations

- Contact Us

- USS Case Studies

- USS Case Studies

- Self-Storage Fit-out For Raked Ceiling Building

- Mezzanine And Staircases For Entertainment Venue

- New Mezzanine And Staircases For Major Retailer

- Mezzanine Pallet Safety Gate

- Self-Storage Fit-Out Project For Brand New Facility

- Warehouse Racking, Wire Mesh & Shelving for New Warehouse

- Self-Storage Partition System & Components Installation

- Self-Storage Store Mezzanine And Staircases

- Multi-Tier Mezzanine For Logistics & Distribution Facility

- Warehouse Plant Platform

- Self-Storage Facility Space Expansion

- Mezzanine Floor For Distribution Warehouse

- Bespoke Feature Staircase & Mezzanine

- Single Level, Multi-Use Mezzanine

- Mezzanine For A New Building

- Mezzanine Floor For Plumbing Supplies Warehouse

- New Racking System and Mezzanine Floor

- Car Park Conversion To Self Storage Facility

- Pallet Racking and Cantilever Racking For Warehouse

- Two Mezzanine Floors For Self-Storage Facility In Birmingham

- Our Accreditations

Making Every Space Count for Businesses All Over the UK

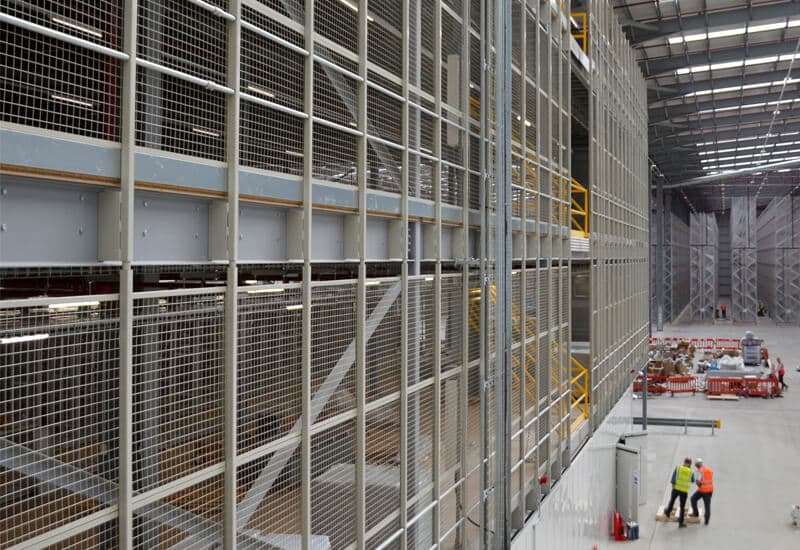

Multi-Tier Mezzanine For New Build Logistics & Distribution Facility

read

A project to incorporate dedicated technical workshops for third-party use in a brand new logistics and distribution facility.

The Project

This project involved the construction of a multi-tier mezzanine floor consisting of 3 tiers, each measuring 70m x 42m, along with 2 multi-tier staircases, one of which was enclosed in a fire-rated pod (sealed fire-rated enclosure). Bespoke full height mesh handrails and concertina pallet gates were fitted at every level. In addition, we also installed a twin goods lift.

Our Client

Our client, Readie Construction was commissioned to carry out this project by their global logistics partner.

The Challenge

The new-build logistics and distribution buildings had to incorporate dedicated ‘Tech Centre Workshops’ for use by third-party companies to assemble parts for dispatch from the Distribution Centre.

The incorporation of a multi-tier mezzanine and additional features for the Tech Centre Workshops provide a single location for logistics, technology and parts assembly and distribution.

USS received an outline enquiry from the main contractor and further information in the form of architect drawings and architect scheme from which we were able to provide a quote which was accepted.

No survey was required as we were working on a new-build structure. The building was built using 3D modelling, with information shared between all contractors working off the same modelling. This meant for example, that the contractor who built the building and those who installed the wall co-ordinated their activities along with other contractors off the same 3D modelling. The submissions were managed and controlled by the architect to create the final plan.

The project was undertaken during the COVID-19 situation with all teams working strictly to Government guidelines.

There were several challenges to be met for this particular project, not least of which were the restrictions and limitations on working conditions caused by the pandemic. In addition, this was a turnkey project with new steel delivered every day – requiring us to execute the planning and coordination for manufacture with meticulous attention to detail and timing.

Over the course of the project, approximately 100 lorry deliveries were made!

We were also able to fulfil the construction of several other steel structures for the client at short notice, which served to keep the project flowing at a faster pace.

And Finally

This was an exciting project with a high-demand for teamwork and coordination of the activities of several contractors on-site simultaneously – notwithstanding the challenges of COVID-19. We are proud to say that the project was successfully completed on time.

We Are Happy to Say

This project involved many contractors working separately while co-ordinating activities to fulfil the scope of work for the additional workshops. The smooth functioning of this project could not have been achieved without the attention to detail and dedication of each and every member of the USS team. At every juncture, we were confident that we would meet the deadlines and delivery standards required and that a successful completion was always USS's number one priority.

Project ManagerReadie Construction Limited

About Us

Find Us

S & L United Storage Systems Ltd

United House, The Street

Takeley, Bishop's Stortford

Hertfordshire, CM22 6QR

Company No. 1313816

VAT No. 291616253Say Hello

01279 871 787Copyright © 2025 S & L United Storage Systems Ltd. All rights reserved.

- About Us